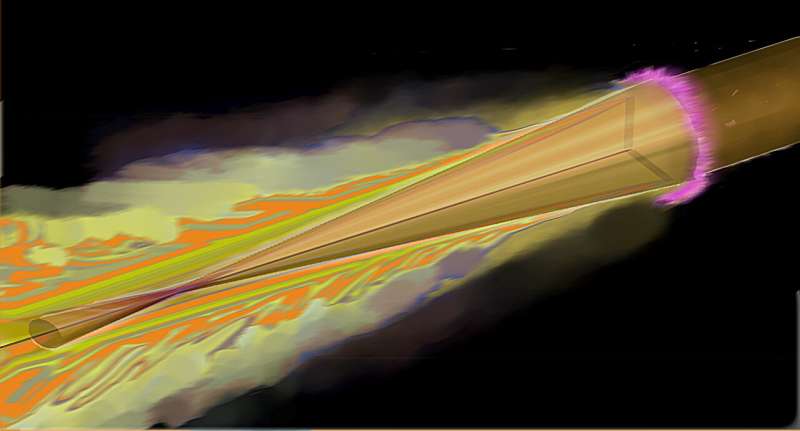

Technical view of the imploding wire: a powerful current of high-energy electrons (pink) heat up, thus driving the shockwaves that compress the wire radially. Credit: HDR / T. Toncian

Terrible conditions exist in the stars and planets. The pressure reached millions of bars, and it could be millions of degrees hot. Sophisticated methods make it possible to create such a speech situation in the laboratory – although only for visual reflection and in low volume.

Currently, this requires the most powerful lasers in the world, such as the National Ignition Facility (NIF) in California. But there are only a few of these light Refeiim, and the possibility of testing is correspondingly small.

A research group led by the Helmholtz-Zentrum Dresden-Rossendorf (HZDR), together with colleagues from the European XFEL, has now succeeded in creating and observing critical conditions using very small lasers. At the heart of the new technology is a copper wire, better than a human hair, as the team reports in the newspaper Natural communication.

At present, the professional laser cutting machine can be very high in the sample material, usually the foil is very small. This causes the surface to heat up suddenly. This creates a wave that runs through the sample. It gathers things and heats them.

For a few nanoseconds, conditions arise as those in the interior of the planet or in the shell of the star. A small window of time is sufficient to study this phenomenon using special measurement techniques, such as the European X-ray X-ray detector at Schenefeld near Hamburg, Germany.

With Europe’s most powerful X-ray laser, HZDR leads an international team called HIBEF-Helmholtz International Beamline for Extreme Fields. Among other things, this consortium is working on the laser at the High Energy Density (HED-HIBEF) experimental station, which produces ultra-short pulses that do not have a particularly high energy-only about one joule. However, at 30 femtoseconds, they are so short that they produce 100 terawatts. The research team used this laser in HED-HIBEF to burn a thin copper wire, only 25 micrometers thick.

“Then we can use the powerful X-ray beam from Europe’s XFEL to see what’s going on inside the wire,” said Dr. Alejandro Laso Garcia, a journalist explains. “The combination of a short-pulse laser and an X-ray laser is unique in the world. It is only thanks to the high quality and sensitivity of the X-ray beam that we can see this unexpected effect.”

A concentrated shock wave

In many measuring systems, scientists change the timing between the effect of the laser flash and the X-ray light. This made it possible to record a complete “X-ray film” of the event.

“First, the laser pulse connects the wire and creates a shock wave that passes through the wire like an explosion and eventually destroys it,” said the head of the HIBEF department, Dr. Toma Toncian explains. “But before that, some of the high-energy electrons that are produced when the laser hits, run along the wire.”

These fast electrons heat the surface of the wire quickly and cause another wave. These run hand in hand from all sides to the middle of the wire. For a short period of time, all the shock waves crash there and cause high pressure and temperature.

The tests showed that the density of the copper between the wires was eight to nine times that of “normal,” cold copper.

“Our computer shows that we have reached a pressure of 800 megabar,” says Prof. Thomas Cowan, director of the HZDR Institute of Radiation Physics and founder of the HIBEF consortium says. “That corresponds to 800 million times atmospheric pressure and 200 times the pressure prevailing inside the Earth.”

The temperature is extremely high by Earth standards: 100,000 degrees Celsius.

Concepts for nuclear fusion

These are conditions close to the corona of a white dwarf star.

“Our method can also be used to obtain conditions similar to those found in large gas fields,” insists Laso Garcia. This includes not only famous giants like Jupiter, but also a large number of distant exoplanets that have been discovered in the past few years. The research team also looked at wires made of other materials, such as steel and plastic.

“Plastics are made with hydrogen and carbon,” says Toncian. “Both objects are also seen in stars and their corona.”

The new measurement system should not only be useful for astrophysics, but also for other research areas. Ulf Zastrau, head of the HED team at the European XFEL, says, “Our experiments show in a dramatic way how we can create high densities and temperatures in a variety of materials.” “This will take fusion research an important step forward.” Many research groups and startups around the world are currently working on lasers that combine with advanced lasers.

Principle: A powerful laser beam hits a hydrogen-cooled fuel capsule from all sides and ignites it, with more energy coming out than it put in.

“With our method, we can see in detail what happens inside the capsule when the laser beam hits it,” says Cowan, describing future experiments. “We hope that this can have a significant impact on basic research in this area.”

Other information:

Laso Garcia, A. et al. Cylindrical coils of thin wires by irradiation with a short-range Joule class laser. Natural communication (2024). DOI: 10.1038/s41467-024-52232-6. www.nature.com/articles/s41467-024-52232-6

Provided by the Helmholtz Association of German research institutes

References: Laser and X-ray combo creates star-like state in hair-thin wire (2024, September 12) Retrieved 12 September 2024 from https://phys.org/news/2024-09-laser-ray- combo-star -position.html

This document is subject to copyright. Except for any legitimate practice for study or personal research purposes, no part may be reproduced without written permission. This content is provided for informational purposes only.

#combination #Laser #Xrays #creates #starlike #pattern #thin #hair #wire